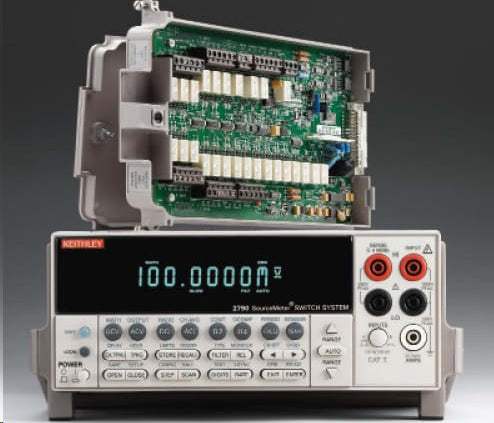

The Model 2790 SourceMeter Switch System is a high voltage, multichannel resistance measurement solution that speeds and simplifies electrical checks of airbag inflators and a variety of other automotive electrical test applications. It is the only commercial instrument that combines all the sourcing, measurement, and signal routing capabilities required to measure insulation resistance and conductor continuity in one compact, affordable package. Through the use of plug-in source/switch modules, the Model 2790 provides programmable high voltage and low current sourc-ing, plus multichannel switching support. This unique combination of capabilities establishes a new standard for price and performance in airbag inflator and other test applications.

Measure Extreme Resistances with Constant Current or Constant Voltage

The Model 2790 uses the forced constant-current method to measure resistances less than 1kΩ. In this technique, the instrument sources a constant current (I) to the resistance and measures the resulting voltage (V). The amount of current sourced is programmable from 0–50mA. Resistance (R) is calculated (and displayed) using the known current and measured voltage (R = V/I). A 20mV dry circuit clamp is available at sourcing levels up to 1mA for preserving the oxide layers on connectors and other components.

For the 1MΩ to 1GΩ resistance ranges, the forced constant-voltage method is used to measure high resistance. This technique optimizes settling speed and reduces noise, allowing faster, high quality insulation resistance measurements. In addition, by applying high voltages (50–500V), the Model 2790 stresses a dielectric while simultaneously measuring its insulation resistance.

In addition to the resistance measurement functions available through the plug-in source/switch modules, the Model 2790’s built-in DMM allows it to make a full range of high precision resistance measurements as well as AC/DC voltage and current, frequency, and temperature measurements. These DMM functions are available either through front panel jacks or through the addition of a Model 7702 40-channel scanner module. In addition to the shorts/open testing performed with the standard Model 7751, 7752, and 7753 switch/control modules, a wide range of supporting measurements can be made. These supporting measurements simplify creating integrated test solutions for hybrid applications, such as testing complex automotive seating systems, which increasingly combine airbag inflators and seatbelt pre- tensioners, seat heaters, switches, motors, etc.

Newly Enhanced Memory Pattern Test Sequencer

The memory pattern test sequencer allows the mainframe to store and execute pre-programmed test sequences for increased testing throughput. Test setups can be stored as unique memory locations and either recalled by number as needed or scanned in sequence to maximize the number of tests per unit time without command transfer delays due to communication or controller.

Model No

2790

Condition

Used

Manufacturer

Keithley

Request A Quote