The professional realm demands the utmost precision and safety, especially concerning electronic test equipment. Let's explore the essential safety practices for electronic test equipment usage that you should integrate into your daily operations.

Understand Your Equipment

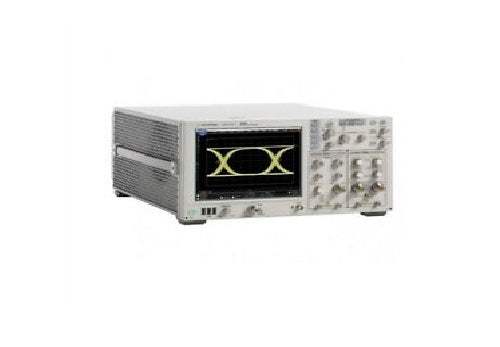

Every piece of electronic test equipment comes with a unique set of specifications and safety features. Before operating, always familiarize yourself with a device’s user manual. This manual is not just a guide to using the equipment but is a comprehensive resource detailing the device's operational boundaries and safety precautions. An in-depth understanding of the equipment can mitigate risks and prevent potential misuse.

Regular Maintenance and Inspection

The functionality and safety of electronic test equipment can deteriorate over time. It's not enough to use the equipment frequently; professionals must ensure regular maintenance. Check for worn-out cables, any inconsistencies in the display, or other signs that might indicate internal faults. Periodic inspections ensure accurate readings and significantly reduce any associated safety hazards.

Avoid Environmental Extremes

Environmental conditions play a significant role in the performance of electronic devices. Extreme temperatures can detrimentally affect their functioning. Likewise, high humidity levels can corrode and damage internal components. Understanding and respecting these environmental thresholds is paramount for professionals who rely on precise readings. Operating within these boundaries ensures equipment longevity and consistent accuracy.

Stay Grounded

Electrical accidents can be severe, and the need to stay grounded cannot be stressed enough when working with electronic test equipment. Professionals should always ensure their workspace is grounded. Implementing practices like wearing anti-static wristbands, especially when dealing with sensitive components, can prevent unintended electrical discharges. These simple precautions can protect the operator and the device from electrical mishaps.

Considering Used Test Equipment

In professional settings, buying used test equipment can be a cost-efficient option. However, there are safety considerations to bear in mind. Always check for a valid calibration certificate when opting for previously owned devices. Ensure the equipment undergoes thorough inspection and, if necessary, recalibration. This ensures the tool's accuracy and safety, affirming that previous usage hasn't compromised its integrity.

Now that you know the essential safety practices for electronic test equipment usage, you should understand that implementing these measures is non-negotiable. Not only do they ensure the user's safety, but they also guarantee the accuracy and longevity of the equipment. In professional arenas, where precision is paramount, these practices are indispensable.